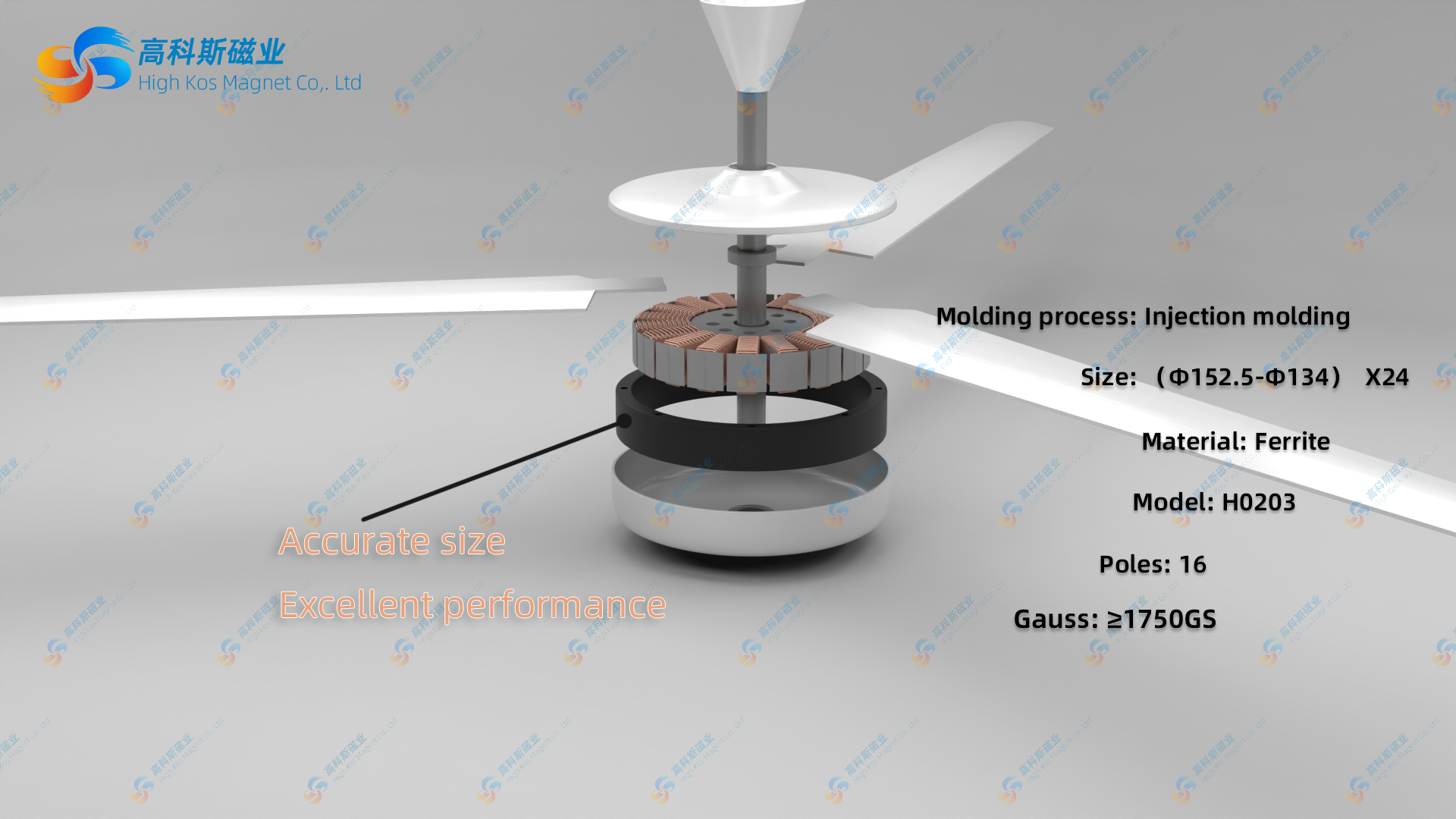

Why do BLDC motors require injection molded ferrite magnetic rings?

Why do BLDC motors require injection molded ferrite magnetic rings?

Traditional BLDC motors often use sintered ferrite, while injection molded magnetic rings are becoming the industry's

preferred choice due to three major breakthroughs:

Ultimate accuracy: ± 0.05mm dimensional tolerance (much higher than sintering process), ensuring uniform magnetic

field distribution and eliminating motor torque fluctuations;

Ultra low eddy current loss: The closed magnetic circuit structure formed by integrated injection molding reduces eddy

current loss during high-speed rotation and improves efficiency by 3-5%;

Anti fragmentation design: resin adhesive buffers mechanical stress, solves the problem of easy cracking of sintered

magnetic rings, and extends the life of the motor.